- ONERA

- Wind Tunnels

- Testing techniques

- Acoustic Measurement

Acoustic Measurement

For several years, ONERA has initiated a program to develop methods and hardware acquisitions in order to perform acoustic measurements in the near- and far-fields of its wind tunnels.

In addition to our dedicated acoustic wind tunnel CEPRA19, acoustic measurements are now possible in the test sections of our S1MA, F1 and F2 wind tunnels.

Near-Field

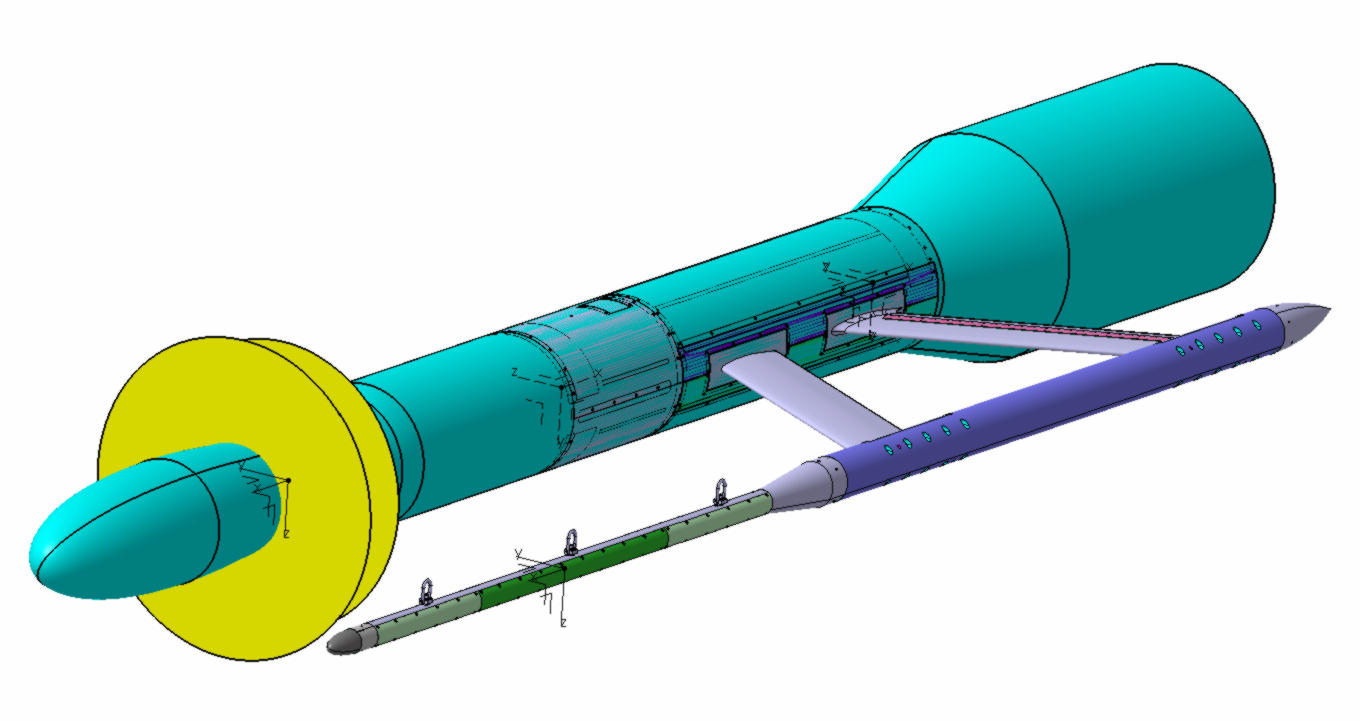

ONERA has an acoustic beam stick equipped with 27 microphones, which provides acoustic measurements in the near-field. Digital signal processing methods have been developed (or are under development) in order to remove the noise reverberations, when making measurements in solid walled test sections

High-speed far-field

Industrial test in S1MA - Open fan configuration - High speed (without liners) + acoustic beam stick

For high-speed (up to Mach 0,82), ONERA has chosen the development of measurement methods not requiring the use of acoustic liners. This approach does not affect the high-quality aerodynamic characteristics of the wind tunnel. In parallel, ONERA has, in recent years, invested in building a suitable antenna network (3 thin acoustic antennas mounted on the walls of the wind tunnel, with 85 microphones in total), and acquiring an acoustic data acquisition system (200 channels, with a 24 bit, 262 kHz maximum sampling rate).

Low-speed far-field

The S1MA wind tunnel can be fitted with a low-speed anechoic test section (fitted with liners), which allows acoustic measurements to be made at low speeds up to Mach 0,30. The far-field instrumentation consists of two rows of 18 microphones each, set in the test section walls, and covered with wiremesh. These microphone rows allow acoustic measurements of both tonal and broadband noise of open rotors. The instrumentation has a bandwidth up to 30 kHz. This innovative instrumentation avoids some very detrimental noise phenomena, such as Hay Stacking with a CROR (Open Fan) model.