- ONERA

- Souffleries

- Testing techniques

- Heat flux measurement

Heat flux measurement

Three methods are used at the Wnd tunnel division for the heat flux measurement:

- Infrared thermography

- Flux meter (thermocouples)

- Thermo-Sensitive paint (TSP)

Infrared thermography

Infrared Thermography is a type of infrared imaging science. Thermography cameras detect radiation in the infrared range of the electromagnetic spectrum (roughly 3-5 or 8-12 µm) and produce images of that radiation. Since infrared radiation is emitted by all objects based on their temperatures, according to the black body radiation law, thermography makes it possible to "see" one's environment with or without visible illumination. The amount of radiation emitted by an object increases with temperature, therefore thermography allows one to see variations in temperature (hence the name).

Infrared (IR) thermography is a two-dimensional, non-contact technique of temperature measurement.

Hardware used can be :

- 1 FLIR SC5600 camera (2.5 to 5 µm), available lens : 12 mm, 27 mm and 54 mm

- 1 FLIR SC7750 camera (8 to 9.4 µm), available lens : 12 mm, 25 mm, 50 mm and 100 mm.

Other cameras can be borrowed from other ONERA Departments.

Studies surfaces must be in insulate material. This material characteristics must be known : thermal characteristics, emissivity (can be determined in Modane ONERA Center on a sample with same roughness than the model).

S3MA flow conditions are : Mach number 0.1 to 3.8, 4.5, 5 and 5.5 ; Total pressure from 0.2 to 7.5 bar (according to nozzle and Mach number). The model is set-up on a sting. The angle of attack and side-slip angle are adjusted before the run. Windbreaks protect the model during the wind tunnel priming and unpriming. When the flow is stabilized, the windbreaks are open for the measurements.

Two cameras can be installed outside the wind tunnel, portside and starboard.

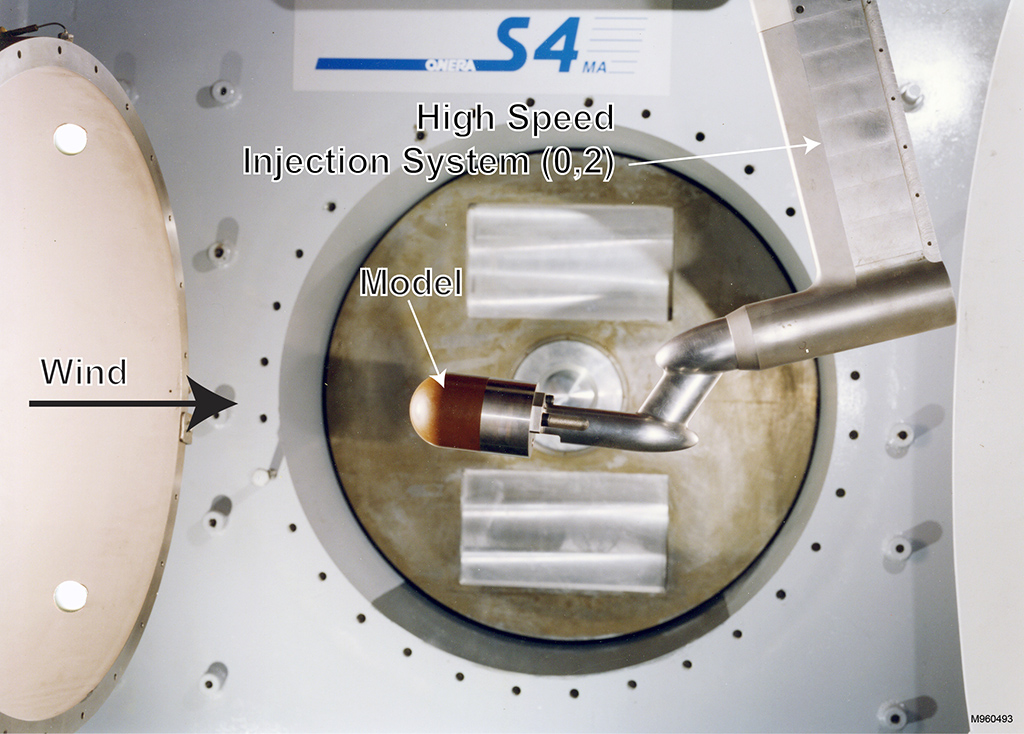

S4A flow conditions are : Mach number 2.7, 6, 10 and 12 ; Total pressure 25 to 120 bar. The model is set-up on a high speed injection system. The angle of attack and the side-slip angle are adjusted before the run. The model is injected at the center of the wind when the flow is stabilized.

Several cameras can be installed in or around the wind tunnel allowing to see model surfaces in all positions.

Flux meter

Flux meter is an inclusive method.

ONERA Wind Tunnel Division has the capacity, during model design, to put ONERA thermocouples in the model and determine heat flux on the model surface. Function of the number of flux meter on the model, it is possible to determine a heat flux cartography on the surface.

Thermocouples are constituted of Chromel (center) and Constantan. Their diameter is 2.7 mm.

Model material must have the same thermal characteristics than the external thermocouple material. The model thickness must be several millimeters in order to measure correct temperatures.

Thermo Sensitive Paint (TSP)

The principle of temperature sensitive paint (TSP) measurement is based on the thermal quenching process of the luminescence of certain molecules incorporated into a binder matrix.

Up to now, infrared thermography method has been favoured.